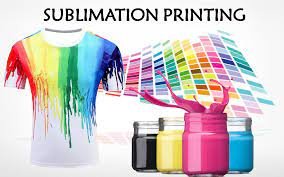

The Ultimate Guide to Sublimation Printing: Techniques, Tips, and Best Practices

- Introduction to Sublimation Printing

In the world of graphic design, sublimation printing has become an increasingly popular

technique. This unique printing method allows for vibrant, high-quality prints that are both

durable and long-lasting. Whether you're a seasoned professional or just starting out,

mastering the art of sublimation printing can greatly enhance your designs and set you apart

from the competition. In this ultimate guide, we will explore the techniques, tips, and best

practices for achieving stunning results with sublimation printing. So, if you're ready to take

your graphic design skills to the next level, keep reading!

2. Understanding the Techniques of Sublimation Printing

To achieve the best results with sublimation printing, it is essential to have a solid

understanding of the various techniques involved. From heat press settings to color

management, each step plays a crucial role in the final outcome of your prints.

One important technique to master is proper heat press settings. The temperature and time

you set on your heat press machine can significantly impact the color vibrancy and durability

of your prints. Experiment with different settings to find the optimal combination for your

specific materials and designs.

Another key technique is color management. Sublimation printing relies on accurate color

representation, so ensure that your monitor is calibrated and your design files are saved in

the appropriate color space. Regularly calibrating your equipment will help maintain

consistency and produce accurate colors across different mediums.

By understanding and honing these techniques, you'll be well on your way to creating

stunning sublimation prints that will impress your clients and set you apart in the world of

graphic design. Stay tuned for our next blog section where we'll dive into some handy tips to

elevate your sublimation printing even further!

3. Tips for Successful Sublimation Printing

Now that you have a solid understanding of the various techniques involved in sublimation

printing, it's time to take your prints to the next level with some handy tips. These tips will help

you achieve even better results and ensure a smooth and successful printing process.

Firstly, it's important to prepare your blank substrates properly. Make sure they are clean and

free from any dust or debris before applying the sublimation transfer. Any impurities on the

surface can affect the final print quality.

Secondly, consider using a protective heat-resistant sheet or parchment paper on top of your

substrate before applying heat. This will prevent any unwanted transfer or bleeding of colors,

especially when dealing with products that have a coated or glossy finish.

Thirdly, pay attention to the drying time for your prints. It is crucial to allow enough time for

the ink to fully dry and set before handling or packaging the finished product. This will prevent

any smudging or smearing of the design.

Lastly, always perform test prints before doing a large production run. This will allow you to

spot any potential issues and make any necessary adjustments before wasting valuable

materials.

By following these tips, you can enhance the quality and efficiency of your sublimation

printing and produce exceptional results that will leave a lasting impression on your clients.

Stay tuned for our next blog section where we'll discuss the best practices for sublimation

printing!

4. Best Practices for Sublimation Printing

In order to achieve the best possible results with sublimation printing, there are several best

practices you should follow. These practices will not only improve the quality of your prints

but also help you streamline your printing process.

Firstly, it's important to maintain a clean and organized workspace. This ensures that dust

and debris don't find their way onto your substrates or transfer paper, which can affect the

final outcome. Regularly clean your printer, heat press, and work area to minimize the risk of

contamination.

Secondly, invest in high-quality sublimation inks and transfer paper. These components play a

crucial role in the printing process and can greatly impact the vibrancy and longevity of your

prints. Don't compromise on the quality of these materials as they directly affect the final

result.

Thirdly, calibrate your printer regularly. This ensures that your prints accurately match the

colors in your image files. Calibration also helps you optimize the performance of your

printer, resulting in consistent and accurate prints.

Moreover, ensure that you use the correct heat and pressure settings on your heat press.

Every substrate requires specific temperature and pressure settings for optimal sublimation.

Refer to the manufacturer's guidelines to determine the correct settings for each type of

substrate you work with.

Additionally, properly time your prints and heat press applications. Too little time can result in

incomplete sublimation, while too much time can lead to color bleeding and dull prints.

Experiment and find the ideal duration for each particular substrate and design to achieve the

best results.

Finally, consider investing in a color management system. This system allows you to

accurately measure and control color throughout the printing process, ensuring consistent

and accurate results. It can be particularly useful when working on larger orders or when

color accuracy is crucial.

By implementing these best practices, you can significantly improve the quality and efficiency

of your sublimation printing. Stay tuned for our next blog section, where we'll explore some

creative ideas and inspiration for sublimation printing projects!

5. Choosing the right materials for Sublimation Printing

In the world of sublimation printing, choosing the right materials is essential for achieving the

best results. The materials you select can have a significant impact on the overall quality and

durability of your prints.

When it comes to substrates, there is a wide range of options available. Some popular choices

include ceramic mugs, polyester fabrics, aluminum panels, and phone cases. It's important to

consider the specific characteristics of each substrate, such as its texture, size, and shape, as

these factors can affect the sublimation process. Make sure to select substrates that are

compatible with sublimation printing and have a smooth, even surface to ensure the best

possible results.

In addition to substrates, the choice of transfer paper is equally important. There are different

types of transfer papers available, including light and dark transfer papers. Light transfer

papers are designed for use with light-colored substrates, while dark transfer papers are used

for dark-colored substrates. Be sure to use the appropriate transfer paper for your specific

project to achieve vibrant and accurate prints.

Furthermore, consider the quality and compatibility of sublimation inks with your printer.

High-quality sublimation inks are formulated to produce vibrant and long-lasting prints. It's

essential to choose inks that are compatible with your specific printer model to ensure

optimal printing performance.

When selecting materials for sublimation printing, it's crucial to research and experiment to

find the best combination that suits your needs. Consider factors such as cost, durability, and

the specific requirements of your projects. By carefully choosing the right materials, you can

enhance the quality of your prints and take your sublimation printing to the next level.

Stay tuned for our next blog section, where we'll dive into advanced techniques and

troubleshooting tips to help you overcome common challenges in sublimation printing!

6. Maximizing the lifespan of sublimated prints

Once you've invested in the right materials and perfected your sublimation printing

technique, it's important to consider how to maximize the lifespan of your prints. By taking

proper care of your sublimated products, you can ensure that they maintain their vibrant

colors and durability over time.

One of the key factors in preserving sublimated prints is proper washing and handling. It's

crucial to follow the manufacturer's instructions for washing and drying each specific

substrate. In general, it's recommended to use mild detergent and wash your sublimated

items in cold water. Avoid using bleach or harsh chemicals, as they can fade the colors of your

prints.

Additionally, take extra care when handling and storing sublimated products. Avoid sharp

objects or rough surfaces that could scratch or damage the prints. Consider using protective

sleeves or packaging to prevent any potential damage during transportation or storage.

Another important factor to consider is exposure to direct sunlight. Over time, prolonged

exposure to sunlight can cause fading of sublimated prints. To protect your prints, consider

displaying them in areas away from direct sunlight, or use UV-protected glass or frames to

preserve their colors.

By following these simple tips, you can ensure that your sublimated prints remain vibrant and

visually appealing for a longer period of time. Taking care of your prints not only enhances

their longevity but also reflects your professionalism and commitment to delivering high-

quality products to your customers.

In our next blog section, we'll delve into the world of color management and how to achieve

accurate and consistent colors in your sublimation prints. Stay tuned to learn more!

7. Troubleshooting common issues in Sublimation Printing

In our previous section, we discussed how to maximize the lifespan of your sublimated prints

by taking proper care of them. Now, let's delve into troubleshooting common issues that may

arise during sublimation printing.

1. Fading or washed-out colors: If your prints are coming out with faded or washed-out colors,

the issue may lie in the temperature or pressure settings of your heat press. Ensure that

you're following the manufacturer's recommended settings for the specific substrate you're

using.

2. Blurry or distorted images: Blurriness or distortion in your prints can be caused by low-

resolution or stretched images. Make sure you're using high-resolution images and properly

sizing them before printing.

3. Uneven or patchy prints: Uneven or patchy prints can be a result of improper pressure

distribution or heat distribution in your heat press. Check that your heat press is properly

calibrated and apply consistent pressure during printing.

4. Ghosting or bleeding: Ghosting or bleeding occurs when the ink migrates beyond the

intended printed area. To prevent this issue, ensure that your substrate is completely flat and

that you're using the correct paper and ink for your specific printer and heat press.

By troubleshooting these common issues, you can achieve high-quality sublimation prints

consistently. Next, we'll discuss the different types of substrates that are compatible with

sublimation printing. Stay tuned!

8. Conclusion: Mastering Sublimation Printing for

Professional Results

In conclusion, mastering sublimation printing techniques is essential for achieving

professional results. By following the tips and best practices discussed in this guide, you can

ensure that your prints come out vibrant, sharp, and durable.

Taking proper care of your sublimated prints, troubleshooting common issues, and

understanding the different types of substrates compatible with sublimation printing will give

you the tools you need to produce high-quality products consistently.

Remember to always follow the manufacturer's recommendations for temperature, pressure,

and time settings, and use high-resolution images that are properly sized to avoid blurriness

or distortion. Maintaining proper pressure distribution, heat distribution, and utilizing the

correct paper and ink will prevent issues such as fading or ghosting.

With practice and attention to detail, you can become an expert in sublimation printing and

create stunning products that will impress your clients and customers. Now, go ahead and

unleash your creativity with sublimation printing!